Product classification

Contact

stamped parts

- Commodity name: stamped parts

- Product Description

-

Features and Advantages

Lightweight and good rigidity: Stamped parts are manufactured with minimal material consumption, resulting in lightweight and rigid components.

High dimensional accuracy: Stamped parts have high dimensional accuracy, with uniform and consistent sizes among parts made from the same mold, ensuring good interchangeability.

Good surface quality: The surface of the material is not damaged during the stamping process, resulting in a smooth and aesthetically pleasing appearance, facilitating subsequent surface treatment.

High production efficiency: Stamping is an efficient production method, and using compound molds and multi-station progressive molds can achieve fully automated production with high efficiency.

Low cost: The production cost of stamped parts is relatively low, making it suitable for mass production.Application Fields

Stamped hardware parts are widely used in various industries, including but not limited to:

Automotive industry: Such as body structural parts, door locks, seat rails, engine brackets, etc.

Home appliance industry: Such as refrigerator door handles, washing machine drums, oven panels, etc.

Electronics and communication industry: Such as mobile phone cases, computer housings, fiber optic connectors, etc.

Construction and home furnishing industry: Such as door and window accessories, furniture hardware, bathroom hardware, etc.

Machinery and equipment industry: Such as various machine tool parts, instrument components, etc.

Aerospace industry: Such as aircraft components, missile parts, etc.

Medical equipment industry: Such as surgical instruments, testing equipment, etc.Production Process

The production process of stamped hardware parts mainly includes the following steps:

Design and drawing: Create 3D models and 2D drawings based on product requirements, determining parameters such as dimensions, shapes, and materials.

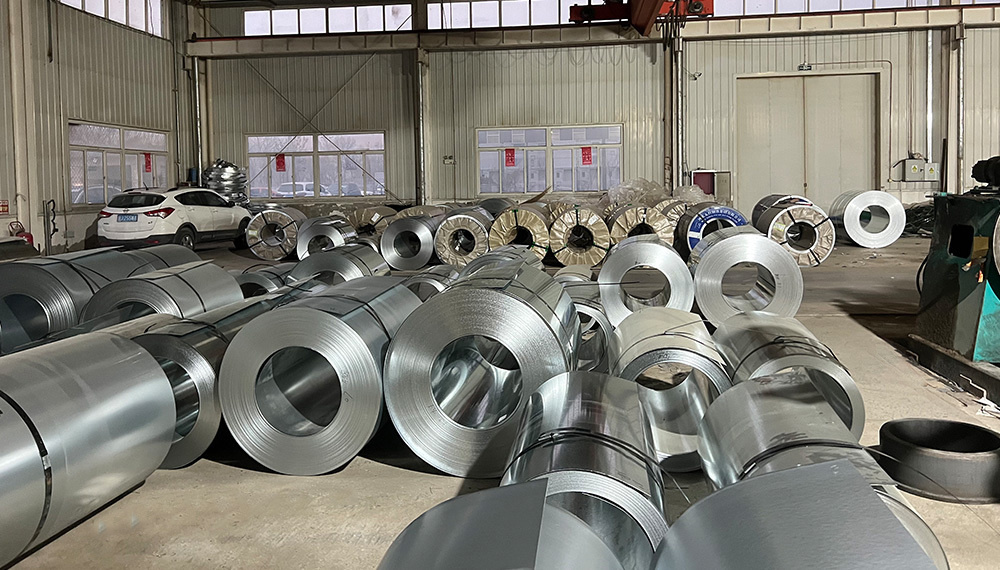

Material preparation: Select and prepare the required metal materials, performing cutting, bending, and other pre-treatments.

Stamping processing: Place the prepared metal materials in the mold and perform stamping processing using equipment such as stamping machines and presses, including blanking, punching, bending, deep drawing, and forming.

Subsequent processing: Clean, deburr, and polish the parts to improve surface quality and precision. Some products may also require electroplating or spraying for surface treatment.

Inspection and packaging: Inspect the appearance and dimensions of the processed parts to ensure they meet requirements before packaging, taking care to protect the parts from damage.

Keywords:

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

Product advantages

Worldwide trusted sheet metal chassis manufacturer and supplier

As a leader in the industry, Cangzhou Xuqiang Electrical Equipment Co., Ltd. focuses on creating a series of high-quality and high-performance product matrices, including but not limited to power cabinets, box-type substations, new energy charging piles and power change cabinets, battery boxes, Data center cabinets, outdoor cabinets, and various precision equipment housings and medical equipment. Our technical team has gathered more than 100 senior technicians. With their profound industry accumulation and exquisite skills, they can quickly respond to customer needs and provide 24-hour uninterrupted technical support and solutions to ensure that every project can be completed on time, according to quality and quantity.

Factory direct sales

Selected Raw Materials

Processing customization

Durable

Intimate after-sales

Timely delivery

Production strength

FAQ

Can you accept small batches?

Do you have a pre-shipment inspection procedure?

Can I get a sample for testing?

What time is the delivery?

What are the payment terms?

Can I have my own customized products?

Related Products

Production of various power cabinets and box transformers; New energy charging piles, power replacement cabinets and battery boxes; Data center cabinets; Outdoor cabinets; Various equipment shells; Medical equipment

The company specializes in producing all kinds of power cabinets and box transformers. New energy charging piles, replacement cabinets and battery boxes; Data center cabinet; Outdoor cabinet; Various equipment shells; Medical equipment.

Contact

Telephone:

+86 18633711199

whatsapp:

+86 15131723865

Mailbox:

Address:

Qingxian Development Zone, Cangzhou City, Hebei Province

Online Message

Cangzhou Xuqiang Electrical Equipment Co., Ltd.